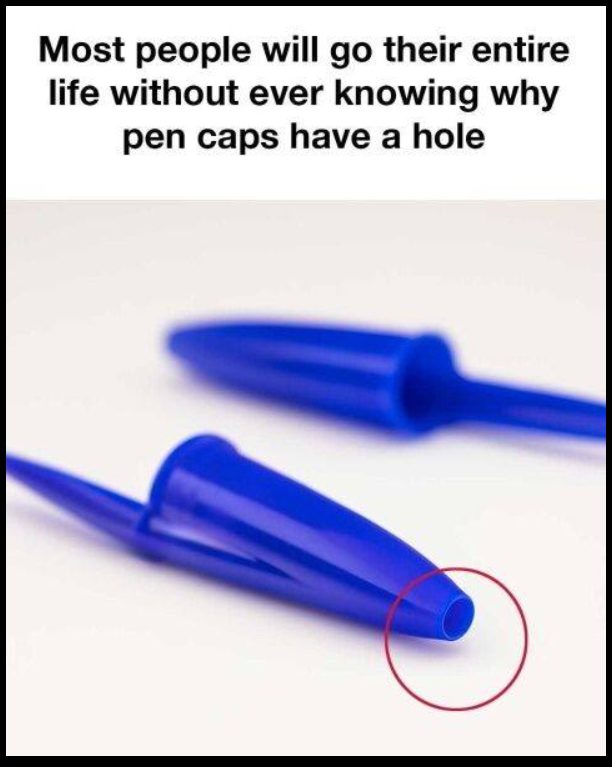

Most people go through life without giving much thought to the small details built into everyday objects, but if you’ve ever noticed the tiny hole in the top of a pen cap and wondered why it’s there, you’re not alone. It might seem like a meaningless design feature, but in reality, it serves several important purposes that combine smart engineering with practical functionality.

To begin with, safety is a top priority. One of the main reasons pen caps are made with a hole is to reduce the risk of choking. If someone accidentally swallows the cap—something that happens more often than you might think—the hole allows air to pass through, which can be crucial in preventing suffocation. This tiny opening can mean the difference between life and death, especially for young children, which is why regulations around the world now require manufacturers to include this feature. It’s a small, almost invisible safeguard, but it has saved countless lives simply by allowing a bit of airflow in emergency situations. However, the hole isn’t just about safety; it also plays an important role in how the pen itself functions.

Pens are sensitive to changes in air pressure, especially when transported or used at different altitudes. Without a hole in the cap to help balance the internal and external pressure, the ink inside the pen could easily leak or fail to flow properly. The hole helps equalize the pressure, ensuring a smooth, uninterrupted ink flow and making your writing experience more consistent and reliable. Anyone who’s ever dealt with an ink explosion during a flight knows just how valuable this tiny hole can be. But that’s not all—the hole also contributes to the manufacturing process in ways that help keep production costs down. When companies make millions of pens each year, even the smallest savings in materials can add up significantly.

By adding a hole to the cap, manufacturers use a little less plastic, which not only saves on materials but also speeds up the cooling and molding process during production. Faster manufacturing times mean lower costs overall, and those savings can be passed along to consumers, making pens more affordable for everyone. In a world where efficiency is key to profitability, such a small feature can have a surprisingly large financial impact. On top of all the practical reasons, there’s also an element of design and branding at play. Some companies use the hole as part of their product’s recognizable look. For example, if you spot a familiar pen cap with a hole, you might instantly associate it with a specific brand known for reliability and affordability.

Incorporating the hole into the overall aesthetic of the pen makes it not only functional but also a subtle part of the brand’s identity. It’s a clever way to use a safety and efficiency feature as a marketing tool without being obvious about it. So the next time you absentmindedly chew on a pen cap during a meeting or toss one onto your desk without a second thought, take a moment to appreciate the engineering that went into that tiny little hole. It’s not just there by accident; it’s a carefully thought-out detail that combines safety, performance, manufacturing efficiency, and even style into one small but mighty feature. This unassuming hole is a perfect example of how some of the most brilliant designs in our lives are the ones we barely notice. Without fanfare, it does its job, making everyday items safer, better, and cheaper without demanding any recognition. The next time you pick up a pen and pop the cap off without a second thought, remember that there’s a world of intelligent design packed into that tiny, often overlooked feature. Smart engineering doesn’t always come with flashing lights and big announcements; sometimes, it’s hidden right there in your hand, quietly making life a little bit better with every word you write.