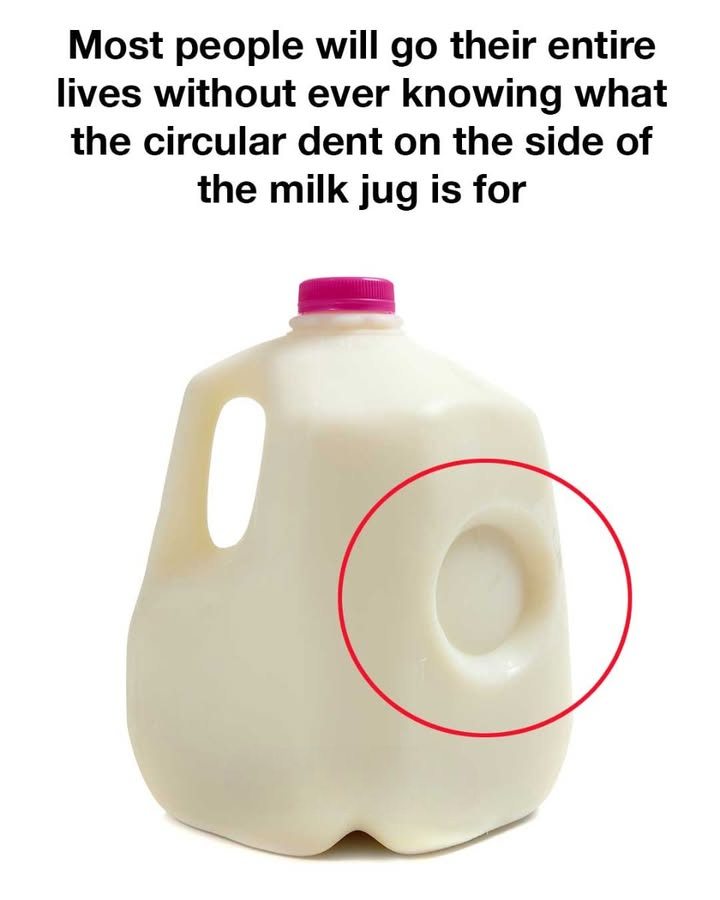

Most of us pour milk from plastic jugs every day without ever giving a second thought to the oddly placed circular dent on the side of the container, assuming it’s just a cosmetic detail or a leftover mark from the manufacturing process. But the truth is, that small dent serves a far more critical purpose than you might expect.

It’s not just a random design element—it’s a functional feature that plays a major role in how the jug handles pressure, maintains its shape, supports safety, and even helps with recycling. Understanding the dent requires us to look beyond what we see and consider the clever engineering that goes into common household products. First and foremost, the dent works as a pressure management system. Milk is a liquid that can expand and contract depending on temperature, especially when it’s being transported or stored in bulk.

When milk heats up, it exerts pressure on the walls of the plastic container, and without a flexible area like the dent, that pressure could potentially lead to cracks or leaks. The dent acts like a pressure release valve, giving the jug space to flex and expand slightly without breaking, helping it withstand everything from temperature swings to being tightly stacked during shipment. But beyond managing internal pressure, the dent is also key to structural strength. The way the indentation is molded helps reinforce the container, allowing manufacturers to use less plastic without compromising durability.

That means the jug stays strong while using fewer materials, which leads to lower production costs. It’s a win-win: cheaper to make and better for the environment. By cutting down on plastic usage while maintaining functionality, this design choice helps reduce the environmental footprint of the packaging process—proof that small design tweaks can lead to big savings in both money and resources. Then there’s the issue of safety and convenience for the consumer. Anyone who’s ever dropped a full jug of milk knows the mess it can make. The circular dent helps absorb impact if the jug is dropped, reducing the chances that it will explode or leak.

This small buffer zone makes the jug slightly more impact-resistant, which is especially helpful in homes with young children or busy kitchens where accidents are bound to happen. By helping prevent spills and container failures, the dent quietly ensures your milk stays where it belongs—inside the jug. Environmentally, the dent also helps when it comes to recycling. Jugs with this indentation are easier to crush and compact, which makes them more efficient to transport and process once they enter the recycling stream. Less volume means less space taken up in trucks and facilities, improving the overall efficiency of recycling operations. In a time when reducing plastic waste is a global priority, even minor design elements like this one contribute to more sustainable systems. And believe it or not, the dent even has a branding and aesthetic function. It gives the jug a distinct shape, one that can be easily recognized on shelves. Some manufacturers even use the dent as a spot to embed logos or company insignias, turning it into a branding tool. This simple feature not only boosts the jug’s functionality but also helps it stand out to consumers visually, reinforcing product recognition in a crowded market. Yet despite all these benefits, many people still assume the dent is either an accident or completely pointless. That’s a misconception. It’s not a flaw or an afterthought—it’s a thoughtful, intentional piece of design born from decades of product evolution. When milk was delivered in glass bottles, they were fragile and heavy. Plastic jugs revolutionized milk storage, and the addition of the dent made them even more durable and efficient. Understanding this small feature helps us appreciate the thought and innovation behind things we use every day. In conclusion, the circular dent on the side of a milk jug might seem insignificant, but it’s a small detail with big responsibilities. From handling pressure changes to improving strength, reducing costs, preventing spills, enhancing recyclability, and even serving as a branding aid, it’s a perfect example of form meeting function. This tiny design element ensures that milk jugs are safer, cheaper, more sustainable, and more effective—and next time you grab one from the fridge, you just might look at it with a whole new level of appreciation.